Biotechnology and Fermentation Facility

The Multi-Scale Fermentation Facility offers services that aim to improve the winemaking process by seeking to enhance the performance of yeast and bacteria.

Teebot96

We are also involved in the identification and evolution of novel yeast strains which offer characteristics such as faster fermentation rates, higher tolerance to ethanol and improved nutrient utilisation.

Based at the University of Adelaide’s Waite campus, the facility is led by researchers from the Wine Microbiology and Microbial Biotechnology Group. The group conducts research into yeast and bacteria, with a specific focus on their application to wine production and in biotechnology.

How we can help you

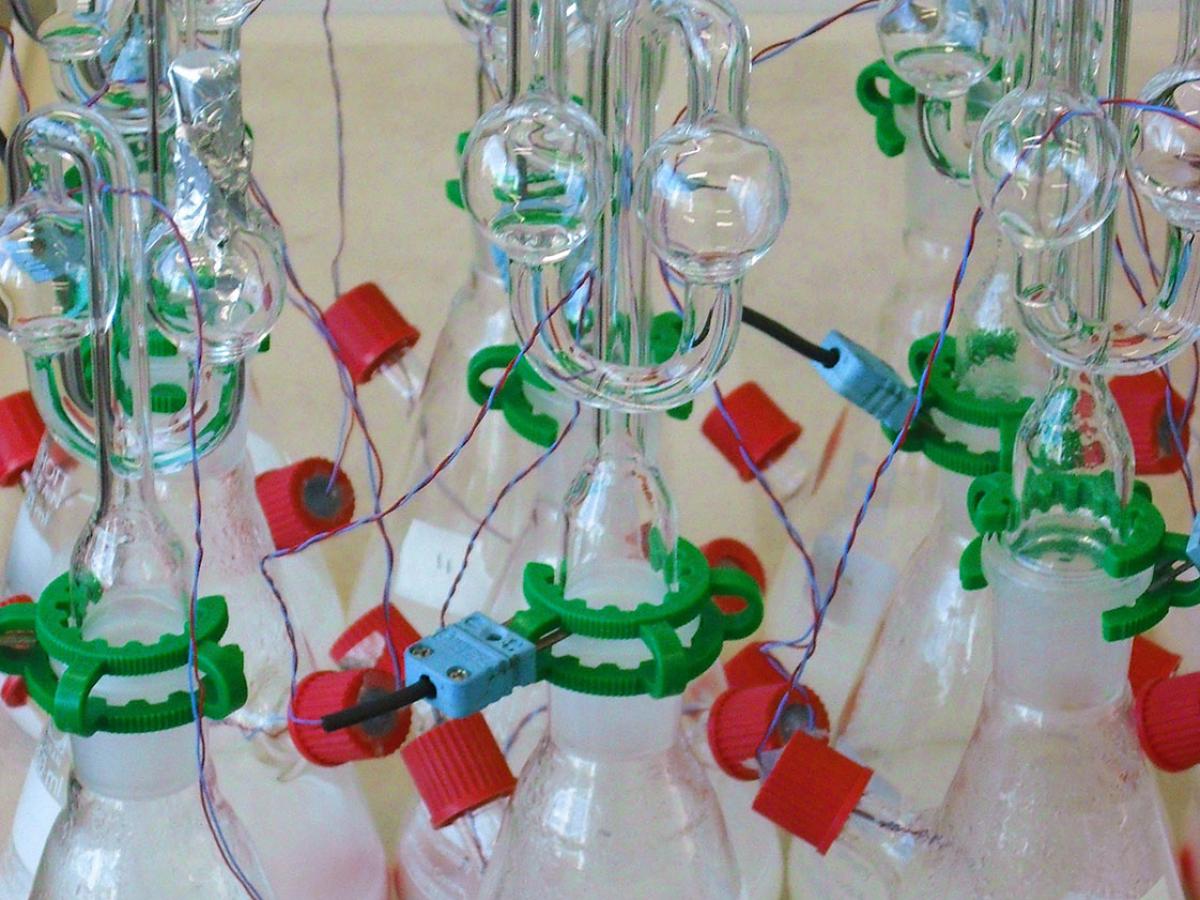

Research focused on the improvement of industrial yeast and bacterial strains catalysed the development of two platforms that greatly reduce the workload associated with measuring and comparing fermentation performance between multiple strains.

Operators need not lose sleep tending to their experiments, as both systems can be directed to take samples unattended at any time day or night.

Samples (0.1-5ml) are collected from independently mixed fermentation vessels into a temperature controlled (ambient to -10 oC) microplate storage unit for convenient analysis.

Medium throughput, 96 x 100ml fermentations, 2 sampling heads

- Four aluminium blocks housing 24 x 100 ml vessels each (96 in total) with integral low-profile airlocks

- Low headspace (60 ml) ensures fermentations will proceed to an anaerobic environment quickly

- Accurate temperature control (+/- 0.5 oC) by 2 recirculation heater/chillers, allowing 2 temperature conditions to be evaluated simultaneously (48 samples in each).

- Sampling of all 96 ferments (1 microplate) takes ~60 minutes

High throughput, 384 x 30ml fermentations, 4 sampling heads

- Integrated liquid delivery system enables initial filling of media and microbial inoculation simplifying experimental setup

- Four water baths, each containing 96 x 30 ml vessels (384 in total) with integral low-profile airlocks

- Very low headspace (8 ml) ensures fermentations proceed to an anaerobic environment quickly

- Accurate temperature control by 2 recirculation heater/chillers, allowing 2 temperature conditions to be evaluated simultaneously (192 samples in each)

- Sampling 384 fermentations (4 microplates) takes ~ 90 minutes

Applications of our research

- Evaluation of many wine or brewing yeasts in a parallel with technical replication.

- Rapid evaluation of a large number of novel strains generated through procedures such as strain hybridisation or directed evolution.

- Evaluation of fermentation additives and treatments.

- Evaluation of organisms where anaerobic culture is required.

- High throughput screening studies of available laboratory yeast deletion and over-expression libraries.

Key partners

Our facilities and services are made possible through generous financial support from:

WA-96 sample unit

ARC- 384 sample unit